Displaying items by tag: Cortec®

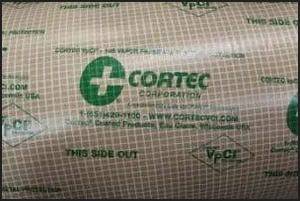

Recyclable Grease-Resistant VCI Paper: Choose the VpCI®-148 Advantage!

What happens when a manufacturer needs to ship a metal part and protect it from corrosion, but the shipping process does not allow removal of process oil? Surprisingly, the answer is not to automatically use VCI plastic but to consider a product like VpCI®-148 Paper—a recyclable, grease-resistant, corrosion inhibiting packaging material produced by Cortec® Corporation and available for distribution worldwide.

Protect Metals from Corrosion

The main benefit of VpCI®-148 Paper is the same as all VCI papers: corrosion protection or rust prevention on the metals packaged within. Like Cortec’s other VpCI® Papers, VpCI®-148 Paper is coated with Vapor phase Corrosion Inhibitors. These protect not only the metal surfaces in direct contact with the paper but also those that are enclosed inside, but not directly touching, the paper. Vapors from the VpCI® coating diffuse throughout the interior of the package, forming an invisible protective molecular layer on the surfaces of the metal. When the metal component is removed from the packaging, the protective layer evaporates on its own—no manual removal needed.

The main benefit of VpCI®-148 Paper is the same as all VCI papers: corrosion protection or rust prevention on the metals packaged within. Like Cortec’s other VpCI® Papers, VpCI®-148 Paper is coated with Vapor phase Corrosion Inhibitors. These protect not only the metal surfaces in direct contact with the paper but also those that are enclosed inside, but not directly touching, the paper. Vapors from the VpCI® coating diffuse throughout the interior of the package, forming an invisible protective molecular layer on the surfaces of the metal. When the metal component is removed from the packaging, the protective layer evaporates on its own—no manual removal needed.

Eliminate Plastic Packaging

VpCI®-148 Paper can effectively replace the use of plastic VCI film or even plastic-coated papers. This is important in a day and age when industries are looking for more renewable resource alternatives to products made from fossil fuels. In addition to the base substrate of VpCI®-148 Paper being made with paper sourced from sustainable forestry, the barrier coating is fully recyclable/repulpable, unlike traditional PE- (polyethylene) or wax-coated papers that cannot be recycled through normal channels.

Resist Grease in Wider Applications

VpCI®-148 Paper holds up better than standard VCI paper in the presence of grease and process oils, allowing it to be used for rust preventative packaging of both dry and oiled metals during storage, transit, and overseas shipment. This is an important solution when protecting metal parts such as bearings that require lubrication, or those where the manufacturing or shipping process do not permit the removal of process oils. Such was the case for a manufacturer of SUV frames being shipped overseas to Germany. The previously used plastic VCI film (non-Cortec®) was breaking down due to aggressive process oils remaining on the frame, resulting in tarnish and corrosion that caused the frames to be rejected. Interestingly, VpCI®-148 Paper solved the unusual problem because it provided corrosion protection and sufficient barrier protection to keep the packaging from breaking down in the presence of process oil. Also, Cortec’s capability of making rolls almost 2.5 meters wide, larger than typical VCI paper, was well suited to wrapping and protecting the wide vehicle frames.

How and Where to Use Grease-Resistant VCI Paper

Thanks to the multiple features mentioned above, there are many potential applications for VpCI®-148. VpCI®-148 Paper protects both ferrous and non-ferrous metals and therefore can be used to protect a wide range of metal parts:

- Carbon Steel

- Stainless Steel

- Galvanized Steel

- Cast Iron

- Aluminum Alloys

- Copper

- Brass (≤30% Zn)

- Solder

VpCI®-148 should be applied by wrapping parts with the printed grease-resistant side facing out and the plain corrosion inhibiting side facing in as close to the metal surface as possible, folding the ends together and taping as necessary to create a closed environment inside the paper. VpCI®-148 Paper can also be used to wrap individual components in combination with a larger integrated packaging solution. It is great for interleaving between trays of parts coated with oil, grease, or process fluids, as well. The next time you have a packaging application that calls for corrosion protection in the presence of greasy or oily parts, consider whether VpCI®-148 Paper may be a sufficient—or even better—alternative to plastic in terms of performance and sustainability. Contact Cortec® to learn more about VpCI®-148 Paper today: https://www.cortecpackaging.com/contact-us/

Tough and Tear Resistant: Cortec® VCI Reinforced Paper for Puncture Prone Metals Packaging

One challenge that metal manufacturers and finishers face is corrosion protection during shipping and storage. Many strategies exist, from coatings and liquid rust preventatives to VCI packaging. The latter has revolutionized the way metals are protected in an enclosed package, replacing greasy rust preventatives with dry corrosion protection. Yet manufacturers with sharp or pointed metal parts have the additional risk of puncture, which could ruin the integrity of the entire package. Cortec® addresses this problem with CorShield® VpCI®-146 Reinforced Paper for heavy-duty puncture prone packaging applications.

Vapor phase Corrosion Inhibitor Protection – How It Works

Vapor phase Corrosion Inhibitor Protection – How It Works

All Cortec® VpCI® brand papers are coated in-house with Cortec’s proprietary VpCI® formula. Vapor phase Corrosion Inhibitors in the coating vaporize and form a protective corrosion inhibiting molecular barrier on metal surfaces wrapped inside the paper. When the component is unpacked, the invisible protective layer does not require cleaning and the part can be used immediately.

VCI Paper - Reinforced

While standard Cortec® CorShield® VpCI®-146 Paper is enough to satisfy the corrosion protection needs of many metals being stored in one place or shipped to another, some circumstances require a tougher grade of packaging. CorShield® VpCI®-146 Reinforced Paper provides two extra benefits for these heavy-duty applications:

(1) CorShield® VpCI®-146 Reinforced Paper offers excellent tear resistance. This is important when packaging oddly shaped metals or those with pointed or sharp edges where puncture could be a concern when handling non-reinforced papers.

(2) CorShield® VpCI®-146 Reinforced Paper also includes a moisture barrier. This not only adds to the durability of the paper but also protects against the ingress of water vapor for moisture sensitive items. This quality is helpful for protecting packages that undergo harsh, high humidity environments. It is also beneficial for packaging parts still covered with grease or process oils that that might leach through or break down standard paper.

How and Where to Use CorShield® VpCI®-146 Reinforced Paper

The traits mentioned above—corrosion protection, tear resistance, and moisture resistance—make CorShield® VpCI®-146 Reinforced Paper easily adaptable to a variety of packaging needs. The standard application method is to wrap a metal item in the paper, fold edges together, and tape the paper folds in place. In addition to single item packaging, CorShield® VpCI®-146 Reinforced Paper can be used for interleaving between layers of metal components, closing the end of shipping tubes, inserting into recessed areas of large packages, and lining crates and boxes where moisture might leach through. Possible items to protect include

• Coils, wire reels, plate, bar, etc.

• Raw and machined forgings and castings

• Sheet metal work, stampings, springs, bearings, fasteners, tubing, pipes, nails, etc.

• Finished goods: engines, machinery, tools, hardware, appliances, instruments, motors, etc.

• Electrical and electronic components, controls, etc.

Whether you find yourself wrapping pipes and rods or metal coils, CorShield® VpCI®-146 Reinforced Paper is a great option for durable corrosion inhibiting moisture barrier packaging protection that resists tearing. Next time you have a puncture prone VCI packaging application, be sure to ask Cortec® about CorShield® VpCI®-146 Reinforced Paper: https://www.cortecpackaging.com/contact-us/